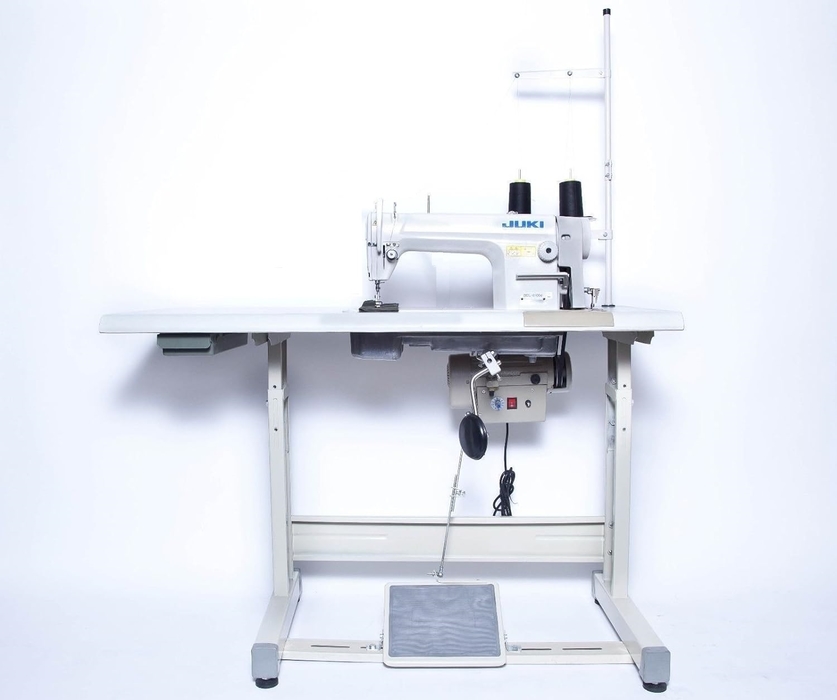

JUKI DDL-8700 High-Speed Single Needle Straight Lockstitch Industrial Sewing Machine With Table and Servo Motor

Our Price:

$999.97

Market Price:

$1099.99

Sold Out

High-Speed Single Needle Straight Lockstitch Industrial Sewing Machine Comes With Table, Legs, Servo Motor, and LED Lamp

Are you looking for an industrial sewing machine that can handle larger projects, such as quilts? Or, are you looking for a new sewing machine for your business?

Professional shops, design schools, and home sewers interested in a sewing machine that handles straight lockstitching on up to a half-inch of fabric will appreciate the JUKI DDL-8700. Solidly built, this machine operates quickly and delivers consistent stitching, making your items look professional and well-made.

Despite being a high-powered industrial machine, the servo motor significantly reduces noise. With smooth, fast, and quiet stitching, you can easily sew for extended periods and complete large projects.

Want to slow down that high-speed stitch? Adjust the servo motor speed as needed to slow it.

Moreover, this high-shank machine is compatible with a wide range of pressure feet, allowing you to expand its functionality effortlessly. By changing the presser foot, you can easily add features like ruffling, gathering, bias, elastic, and zipper installation. With over 200 presser feet available, many of which are high-shank (and high-shank adapters for snap-on feet), the possibilities are endless.

Once you are familiar with the Juki 8700, you'll understand why thousands of buyers swear by their machines.

The JUKI DDL-8700 is high-speed single needles lockstitch machine. It’s for industrial use and produces great stitches. The machine head is durable and consistent. Whether you’re working with lightweight or medium-weight fabrics, this machine can handle them all. That’s why it’s a customer favorite for industrial sewing – efficiency and reliability make it the top choice in the sewing community.

Read the technical specs for uninterrupted sewing. This lockstitch machine runs up to 5500 RPM fast and efficiently. Servo motor for speed control and noise reduction. Weighs 61 lbs. Machine oil is required. 320VA voltage.

Juki DDL-8700 Maintenance

To keep your Juki in good condition and running smoothly. Clean the machine in the bobbin area and needle regularly to prevent build-up that can cause mechanical problems like:

Oil the machine with Juki Defrix Oil No. 1. Regularly check and adjust the thread tension to maintain stitch quality. Here are some maintenance tips:

High-speed machines increase industrial efficiency and productivity by:

This is a great tool for commercial sewing.

Assembling the JUKI DDL-8700 is easy following the manual's step-by-step guide. Unbox all parts and lay them out in order. Attach the machine head to the table using the screws and tools provided. Make sure all screws are tight to avoid any problems.

To keep your JUKI DDL-8700 running long-term, proper installation is key. Mount the machine on a table designed for the Servo Motor sewing machine. Place the machine stand and head in position. Use the provided screws to fasten the machine to the table. This will keep the machine stable during operation so you can sew accurately and efficiently.

By following these steps and maintaining them regularly, your sewing machine will perform and last long in any industrial sewing environment. For more support or questions, contact Goldstar Tool today.

Professionals such as garment manufacturers, tailors and seamstresses, and fashion designers rely on the DDL‑8700 for its speed and consistency in high‑volume production. These users value its ability to maintain stitch quality across a range of light‑ to medium‑weight fabrics.

The DDL‑8700 uses a single‑needle, straight lockstitch. In a lockstitch, the upper thread is carried down through the fabric and interlocked with the bobbin thread beneath it, producing a secure seam that is less likely to unravel. This mechanism is optimized for strong, consistent straight‑stitch seams and is one of the key reasons the machine is a favourite in professional settings.

As an industrial machine, the DDL‑8700 is designed for prolonged, continuous use. Its robust construction, powerful motor, and automatic lubrication system enable long hours of efficient operation in production environments.

In contrast, home sewing machines are built for intermittent use and are not engineered for the high‑volume, high‑speed demands of commercial sewing.

| Model | Primary Fabric Weight | Maximum Sewing Speed | Maximum Stitch Length | Needle System | Uses |

|---|---|---|---|---|---|

| DDL‑8700 | Light‑ to medium‑weight fabrics | 5,500 sti/min | 5 mm | DB×1 (#9 – #18) | — |

| DDL‑8700A | Light‑weight fabrics | 4,000 sti/min | 4 mm | DA×1 (#9 – #11) | Designed for very fine materials; shorter stitch length helps prevent puckering and provides excellent stitch quality. |

| DDL‑8700H | Medium‑ to heavy‑weight fabrics | 4,000 sti/min | 5 mm | DB×1 (#19 – #23) | Engineered for thicker materials; heavier needle system and adjusted speed ensure reliable stitching on heavy fabrics. |

Always turn off the machine before threading or doing anything that could cause injury, such as threading, oiling, changing a needle, or installing a bobbin for sewing.

The 8700 has a finger guard on the shaft to prevent injury and needle breakage. If you’re having trouble threading the machine, we suggest getting a pair of long tweezers to help.

Keep your hands, hair, and anything else that could become caught away from the machine's bobbin hook, needle area, and other moving parts.

Continuously operate the 8700 with a whole pan of oil. Check your machine’s oil pan regularly before and after use to ensure smooth operation and prevent damage.

And, of course, read the accompanying instruction manual, safety manual, and setup sheet with your machine.

90 Days labor on defects in materials and workmanship.

** Head Only option does not include the table, legs, Servo Motor, and LED Lamp. No assembly or residential charges necessary.

Feed Dog 1: Light-Weight, Medium-Weight, Heavy-Weight

Feed Dog Screw: #10601

Needle Plate/Feed Dog Combo: Needle Plate/Feed Dog Combo

Needle Plate Screw: 11/64-40 L=8.5MM - #SS-2110920-TP

Needle Bar: #229-06002

Needle Bar Set Screw: #SS-7080510-TP

Needle Bar Thread Guide: #229-0630

Needle Bar Thread Guide Screw: #SS-7080510-TP

Presser Foot Screw: #SS-7091110-TP

Presser Foot Assembly: B1524-012-0A0

Thread Tension Assembly: #229-62054

ACCESSORY KITS

Starter Kit For Industrial Sewing Machines

Deluxe Kit For Industrial Sewing Machines

PRESSER FOOT KITS

5 Pack Industrial High Shank Presser Feet

Glide-On Industrial High Shank Presser Feet (5 Pack)

SEWING GUIDES & GAUGES

Magnetic Sewing Machine Gauge Guide

Quilters Swing Sewing Guide

Swing Gauge #5812

T Gauge (2-1/2")

Adjustable Seam Guide

Sewing Machine 3 Corner Gauge #25873

Swing Away Roller Guide Short Arm

ZIPPER/CORDING/WELTING/PIPING

Invisible Zipper Presser Foot #S518

Split Hinged Zipper Presser Foot #40322SH

Narrow Right Hinged Cording Foot #12435HN

Narrow Left Hinged Cording Foot #31358HN

Wide Left Hinged Cording/Zipper Foot #31358HWL-P36L

Wide Right Hinged Cording/Zipper Foot #12435HWR-P36

High Shank Double Welting/Piping Foot #36069DG

Metal Piping Foot (Right Or Left) #36069L, 36069R

Welting/Piping/Cording Presser Foot #767415000

COMPENSATING

Left Compensating Presser Foot

Right Compensating Presser Foot

Compensating Binder Presser Foot

Compensating Foot 211-14

SHIRRING/GATHERING

Shirring/Gathering Foot #120828

Shirring/Gathering With Adjustable Blocks #S950

Shirring/Gathering Screw Adjusting Presser Foot #S952

Shirring/Gathering Tape Guide Elastic Adjustable Presser Foot #S537

GUIDE FOOT

Hinged Right Guide Foot

BUTTONHOLE FOOT

High Shank Buttonhole #CY-703H

HEMMER

Ball Hemmer Foot (Double Fold) #490358

Spring Hemmer Foot #490359

Hemming Presser Foot and Folder Set #F502

CENTER TUBE

Hinged Center Tube Presser Foot #S10C

ROLLER

Small Roller Foot With Needle Plate & Feed Dogs

Large Roller Foot With Needle Plate & Feed Dogs

SPK Roller Foot #SPK3

BIAS

Bias Tape Binding Presser Foot #6288

STRAIGHT STITCH

Hinged Straight Stitch Presser Foot #P351

Hinged Straight Stitching Foot #24983

Hinged Narrow Presser Foot #142058N

Heavyweight Straight Stitch Presser Foot - Brother #SA173

Straight Stitch Presser Foot With Finger Guard #351

GLIDE-ON/TEFLON

Glide-On Invisible Zipper Presser Foot #S518NST

Glide-On Standard Extended Tail Hinged Presser Foot #MT-18

Glide-On Welting/Piping/Cording Presser Foot #36069T

Non-Stick Glide-On Presser Foot #T-350

Universal Glide-On Hinged Narrow Zipper Presser Foot #T-363

Universal Glide-On Left Narrow Zipper Presser Foot #T36LN

Universal Glide-On Right Narrow Zipper Presser Foot #T36N

FOR QUILTING

Quilters Swing Sewing Guide For Industrial Sewing Machines

1/4" High Shank Clear Ruler Foot For Free Motion Quilting

1/4" High Shank Metal Ruler Foot For Free Motion Quilting

Metal Quilting Glide Foot and Needle Plate #GS1Kit

Quilter Foot with Guides - Singer #S521

BINDERS/FOLDERS

Raw Edge Binder Set #S64

Raw Edge Plain Tape Binder Binding Attachment #100LS

Right Angle Binder Set #S60

Double Fold Binder / Binding Attachment Folder #508L

Top Mount Collarette Binder Top Clean

HEMMER

Single Fold Up Turn Hemmer #S75U

Shirt Tail Hemmer Set #S70

BUTTONHOLER

Buttonholer Attachment #YS-4455

RUFFLER

Deluxe Ruffler Attachment for Industrial Sewing Machines #G900E

The needles with your JUKI are the Organ DBx1, available on our website. This machine uses size 16×257, size 8 through 20 or 16×97. The 8700 can also use standard needles, sizes 9 through 21, universal or fabric-specific needles such as knit.

A pan directly underneath the machine supplies oil to the machine with a cotton wick. Lift the machine up and over to access the oil tank while on the table. You must keep the machine’s oil level consistently at the «high» mark, either by adding more oil or draining it and refilling it as needed. If the oil pump can’t get the oil into the machine, it can cause serious problems later.

You need a specific type, like motor oil in your car, to keep this machine running. The DDL-8700 requires JUKI New Defrix Oil No.1, equivalent to ISO VG7.

Our table has legs and is 22"w x 47"l. It includes a knee and foot pedals and a left-hand drawer for accessories.

No. The 8700 only does straight stitching, with a horizontal bar on the right side for a reverse stitch.

Because of the Servo motor speed control, most users find the machine more straightforward to use. Both beginning and seasoned sewers find this feature helpful when stitching projects that don't demand high-speed stitching.